Dependable Welding Inspection Service for Quality Control

Dependable Welding Inspection Service for Quality Control

Blog Article

Discover the Benefits of Various Types of Welding Services for Your Organization

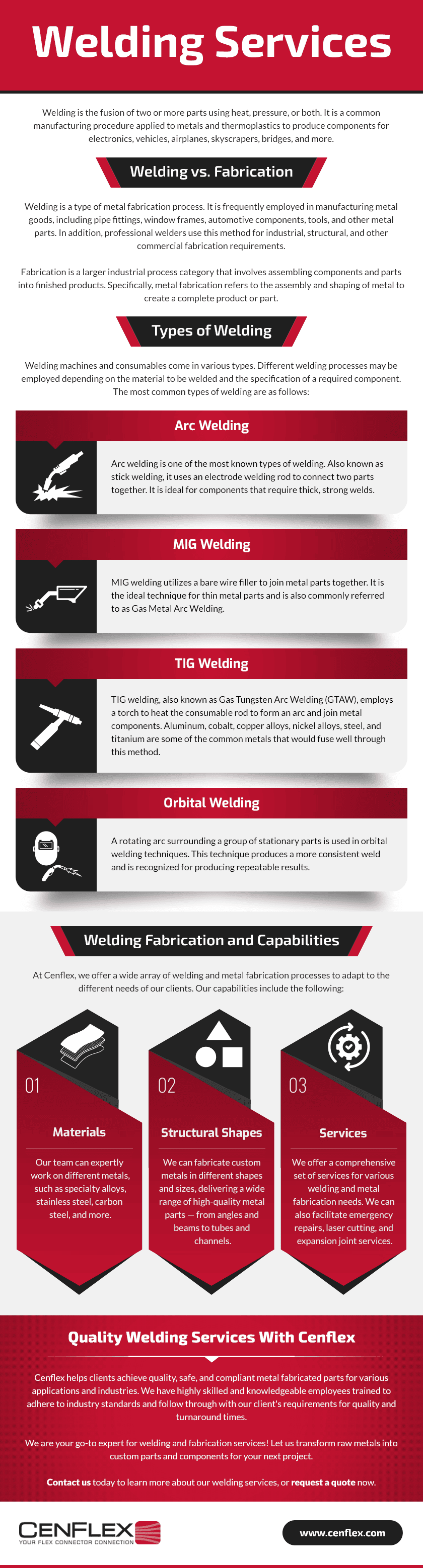

In the realm of industrial operations, the choice of welding services plays a pivotal function in identifying the high quality and efficiency of your company processes. Each welding method, from MIG to TIG, Arc, and Area welding, offers distinctive advantages that cater to particular needs and needs. Understanding the subtleties of these welding approaches and exactly how they line up with your service goals can significantly influence your lower line and operational success. As you navigate the elaborate landscape of welding solutions, revealing the unique benefits they give the table comes to be not simply an option yet a calculated imperative for your organization growth and competitiveness.

MIG Welding Advantages

MIG welding, additionally called Gas Steel Arc Welding (GMAW), supplies countless advantages to services looking for efficient and high-quality welding solutions. One main benefit of MIG welding is its convenience in managing numerous kinds of metals, consisting of stainless-steel, light weight aluminum, and mild steel. This versatility makes MIG welding a preferred option for industries with varied welding demands.

Moreover, MIG welding is a cost-effective option due to its reliable use consumables such as filler material and protecting gas. This performance equates to savings for organizations in the lengthy run. On the whole, MIG welding's combination of versatility, speed, simplicity of usage, and cost-effectiveness makes it a preferred choice for many welding applications.

TIG Welding Advantages

Tungsten Inert Gas (TIG) welding offers exact control and phenomenal top quality in welding services for services calling for thorough and high-standard welds - Welding Inspection Service. TIG welding stands out for its capacity to generate tidy and precise welds without spatter or triggers, making it optimal for applications where appearances and precision are paramount. One of the vital benefits of TIG welding is its versatility in welding various kinds of metals, consisting of stainless steel, light weight aluminum, copper, and unique steels, supplying services with an adaptable welding service for different projects

In addition, TIG welding makes it possible for welders to work with thinner products efficiently, as the process allows for reduced heat input and better control over the welding arc. Overall, the accurate control, top notch welds, and convenience make TIG welding a favored selection for organizations looking to attain superior welding results.

Arc Welding Pros

Place Welding Advantages

Area welding uses numerous benefits for services seeking precise and efficient signing up with of metal parts in their manufacturing processes. This welding approach is very economical because of its quick implementation, marginal need for comprehensive preparation, and reduced energy intake contrasted to other welding techniques (Welding Inspection Service). Spot welding also supplies a clean and neat surface, making it suitable for applications where looks are critical

One of the crucial advantages of spot welding is its capability to create strong and sturdy bonds in between steel surfaces. The process produces a concentrated heat source, resulting in a local weld that lessens damages to the surrounding areas. This focused heat application additionally lowers the danger of warping or distortion in the bonded materials, ensuring the honesty of the final item.

In addition, place welding is highly functional and can be utilized on a wide array of alloys and steels, consisting of aluminum, copper, and steel. Its versatility makes it a prominent selection for industries such as automotive, electronics, and aerospace, where accuracy and performance are extremely important. Overall, the benefits of spot welding make it a valuable property for companies looking to enhance their home manufacturing abilities.

Welding Solution Option Factors

Some welding methods are better matched for small-scale and detailed tasks, while others are extra efficient for larger and much more simple structures. Take into consideration the speed and performance of the welding procedure. By meticulously taking into consideration these elements, you can pick the most appropriate welding solution for your service needs.

Verdict

Finally, recognizing the benefits of different kinds of welding solutions can substantially benefit companies in their decision-making process. MIG welding supplies effectiveness and speed, TIG welding provides high precision and clean welds, arc welding is cost-effective and functional, and area welding is optimal for signing up with slim materials. By thinking about these variables, companies can choose one of the most suitable welding solution to meet look at these guys their details needs and demands.

MIG welding, also understood as Gas Metal Arc Welding (GMAW), uses various advantages to businesses looking for effective and high-grade welding services. One of the crucial benefits of TIG welding is its flexibility in welding various types of steels, including stainless steel, light weight aluminum, copper, and unique metals, providing organizations with a flexible welding service for numerous jobs.

Arc welding is known for its high welding rate, enabling reliable completion of welding jobs (Welding Inspection Service). Overall, the pros of arc welding make it a valuable welding service for companies looking for a flexible, economical, and effective welding service

MIG welding provides efficiency and rate, TIG welding supplies high precision and tidy welds, arc welding is flexible and affordable, and area welding is perfect for signing up with thin products.

Report this page